|

Ningbo Shuangsheng Plastic Machinery Co.,Ltd

|

50 Tons small injection molding machine

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Customized injection molding machine

2.Small, precise, professional

3.12-year manufacture experience

4.60g injection weight

Since the establishment in 2002, our Shuangsheng brand has obtained good reputation from customers at home and abroad, our small sized series injection molding machines are featured with small, precise, profeesional and stable.

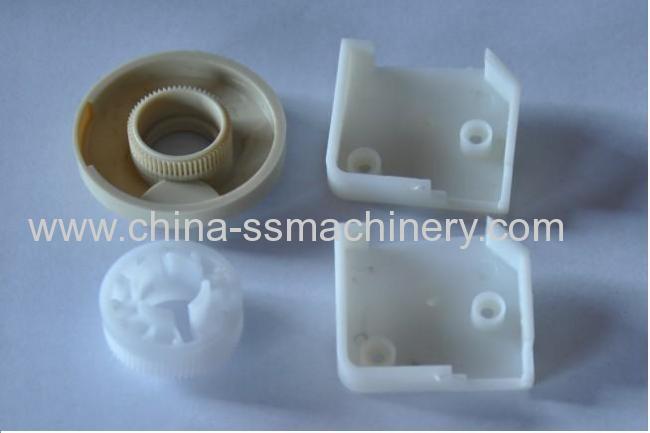

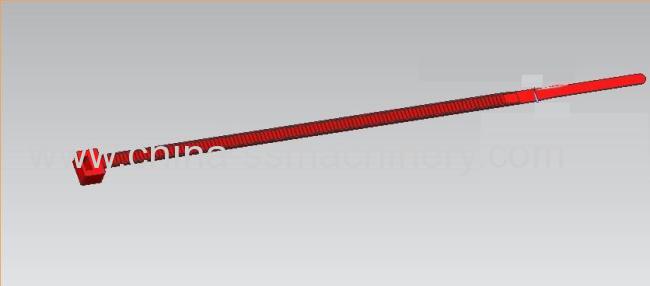

Machines size ranges from 25Tons to 168Tons, with injection weight from 20g to 400g, the machines are widely applied to produce small precise gears, masterbatch or pigment color chips, PVC fittings, PET preforms, bottle caps, bowls, plastic toys such as Barbie, cars, eletrical junction boxes, sockets, nylon zip ties and other plastic products that of injection weight within 400Grams.

Shuangsheng SSF-series small injection molding machine is a strong open platform, which can meet the customer's special request, like adding special features so as to suit all kinds of process techniques.

In order to provide good service to customers, we have established good cooperation with mold and auxiliaries supplier, they can provide the best quality molds, hopper dryer,chiller,autoloader,crusher for you, that works on well with our machines.

50 Tons small injection moulding machine

1.Main products;

A.Fixed pump injection molding machine(SSF-K5)

B.Servo motor energy saving injection molding machines(SSF-S)

C.Special purpose machine for lab test.

D.

2. Advantage:

Strong Technical design ability, Stable quality, and large production capability, Famous brand.

3. Machine description:

Control system: All-digital control system uses dedicated controller, multiple CPU processing division,

a multi-functional automatic fault detection, alarm system, certificates 199 mold of

processing procedures, with remote control interface. System is of high stability and

responsiveness. System uses color LCD, man made interface for easy operation and

with a number of peripheral interfaces.

Features:

- Multi-lanagues.

- Manual, semi-automatic and fully automatic mode.

- To provide EUROMAP robot interface.

- Automatic movement monitoring with alarm and fault diagnosis.

- Function of slope setting can set the start and stop of movements, so as ensure the smooth movement.

Hydraulic system;

Advanced hydraulic system design, through proportional control of pressure, flow achieves rapid multi-level pressure, speed switching, the system configuration is reasonable, stable and reliable. The noise is less than 75 DB.

Machine features;

- There are three or four screws and barrels with optimal design, respectively, nitride, hard plating, bi-metal, which is suitable for different processes of a variety of plastics. and the choice of product.

- Two-guided guided supports, double-balanced rapid injection.

- The high-torque hydraulic motors offer a stable plasticizing capacity, high precision electronic device position detection enable accurate measurement.

- Multi-injection speed and pressure and multi-level holding pressure settings, switch from the injection time, location, pressure control to ensure the quality of molding.

- Multi-level back-pressure of pre-plastic and pre-speed are computer-controlled, automated auto purge.

- Expected to prevent cold-start function to ensure that the screw and barrel will not be harmed. Stability of the injection unit.

- Security doors fitted with hydraulic, mechanical and electrical interlocking triple safety device. When the safety door is open, the machine cannot clamp.

- Low pressure mold protection device to prevent damage to platen.

- Hydraulic ejector, adjustable stroke, and top speed of ejector in and out, for multiple actions.

- Flexible tie bars nut eliminates fatigue fracture; assure the working life of tie bars

- Automatic height adjustment. The replacement of different mold, the parameters set by clamping force to achieve the automatic adjustment.

- High-precision electronic detection device, multi-stage control of opening stoke, speed and location, location accuracy.

Here we would like to post our hot sale 50Tons small injection molding machine parameters, this model is this year's hot sale products, with annually sold over 100sets.

| Items | Parameter | Unit | Parameter Value (SSF500-K5) | |

| Injection Unit | Screw diameter | mm | A | B |

| 28 | 30 | |||

| Screw L/D ratio | L/D | 19 | 17.7 | |

| shot volumn (theoretical) | Cm3 | 70 | 80 | |

| injection weight(PS) | g | 64 | 73 | |

| plasticizing capacity | g/s | 6.9 | 7.7 | |

| injection rate | g/s | 43 | 49 | |

| injection pressure | Mpa | 224 | 195 | |

| screw speed | rmp | 200 | ||

| Clamping unit | clamp force | KN | 500 | |

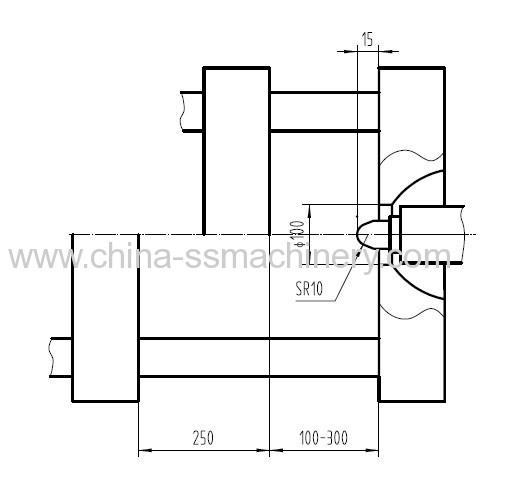

| open stroke | mm | 250 | ||

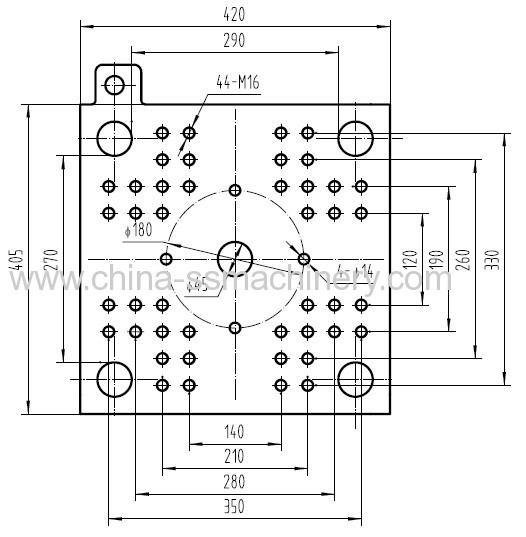

| space between bars (W*H) | mm | 290*270 | ||

| max mould height | mm | 300 | ||

| min mould height | mm | 100 | ||

| ejector stroke | mm | 65 | ||

| ejector force | KN | 20 | ||

| ejector number | PC | 1 | ||

| mould align diameter | mm | 100 | ||

| Others | max pump pressure | Mpa | 16 | |

| pump motor power | KW | 5.5 | ||

| heating power | KW | 4.7 | ||

| machine dimension | m | 3.2*1.1*1.6 | ||

| machine weight | T | 1.9 | ||

| oil tank capacity | L | 115 | ||

Platen dimension;

Parts list that can be made by our small injection molding machines but not limited;

Agent wanted

In order to bring our machines to more customer worldwidely, we are sincerely to invite distributors to get exclusive agency agreement from us, we promise to provide you the competitive price with good services.

What we request you is to have a robust sales and maintetance team for customer end machine instalaltion and debugging, provide on time aftersales service to customers, to make our brand known in your market.

We have signed agency agreements with distributors in Argentina, Denmark,Poland,Russia,Turkey.

Welcome your join-in.