|

Ningbo Shuangsheng Plastic Machinery Co.,Ltd

|

Electricity saving injection molding machine

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. ISO9001:2008

2. T-slot mold platen

3. Easy for operation

4. Aftersale service fast response

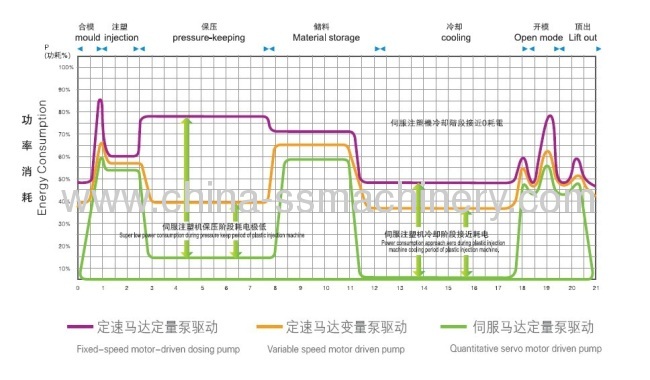

5. Energy saving, saves consumption 20~80%

Energy saving plastic injection molding machine

140T energy saving plastic injection molding machines featured with;

Big tie bar space and shot weight capacity;

World famous component parts;

Competitive price and quality guarantee.

It can be widely used to produce all kinds of plastics parts, with characters of high efficiency and good performance.

Template structure of the high-rigidity design, both T-slots and conventional screw holes make mold is easy to install;

Parameters as below;

| Items | Parameter | Unit | Parameter Value (SSF1480) | ||

| Injection Unit | Screw diameter | mm | A | B | C |

| 38 | 42 | 45 | |||

| Screw L/D ratio | L/D | 22.1 | 20 | 18.6 | |

| shot volumn (theoretical) | Cm3 | 193 | 235 | 270 | |

| injection weight(PS) | g | 176 | 213 | 246 | |

| plasticizing capacity | g/s | 6.2 | 7.5 | 8.7 | |

| injection rate | g/s | 94 | 115 | 132 | |

| injection pressure | Mpa | 208 | 171 | 149 | |

| screw speed | rmp | 185 | |||

| Clamping unit | clamp force | KN | 1480 | ||

| open stroke | mm | 380 | |||

| distance between tie bars (W*H) | mm | 410*410 | |||

| max mould thickness | mm | 450 | |||

| min mould thickness | mm | 160 | |||

| ejector stroke | mm | 120 | |||

| ejector force | KN | 50 | |||

| ejector number | PC | 5 | |||

| dia of mould location hole | mm | 125 | |||

| Others | max pump pressure | Mpa | 16 | ||

| pump motor power | KW | 13 | |||

| heating power | KW | 9.3 | |||

| machine dimension | m | 4.5*1.35*1.9 | |||

| machine weight | T | 4 | |||

| oil tank capacity | L | 250 | |||

The computer controller of this plastic machine is featured with;

1.Open-type PLC interface technical edition & on-line amendment.

2.USB connection, copy, edition and amend procedure easily.

3.I/O automatically detect & use of ASIC to simplify circuit to ensure the reliability of PID closed-loop type of barrel heating & temperature deviation of the precise control of self-tuning.

4.Multilanguage selection with colorful screen.

5.The data stored without the requirement of battery, no need to worry lost datas.

Our plastic injection molding machines are stricty controlled upon ISO9001:2008 quality requirements.

Plastic injection molding machine energy saving chart;